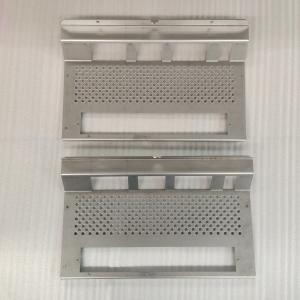

Stainless Steel Bending Sheet Metal Enclosure Fabrication Wind Power Parts

Laser Cutting Operation

- Material Selection: Choose the appropriate sheet metal material based on the project requirements, considering factors such as thickness, material type, and surface finish.

- Laser Cutter Setup: Configure the laser cutting machine, adjusting parameters like laser power, cutting speed, and focal length for the specific material and thickness.

- Computer-Aided Design (CAD) Import: Import the digital design file (CAD) into the laser cutting machine's software, specifying the desired cutting path.

- Laser Cutting: Activate the laser cutting process, allowing the focused laser beam to precisely cut through the sheet metal along the defined path.

- Quality Inspection: Inspect the cut edge for accuracy, smoothness, and any signs of thermal distortion, ensuring it meets the project's quality standards.

Material Available:

- Steel Plates: Q235, Q345, 08, 08F, 10, 10F, 08A1, SPCC, SPCD, SPCE, st12, st13, st14, st15, st14-T, CT-3kП,08kП,08ПC, SPHC, SPHD, SPHE,

- Other Steel Plates: Zinc Plating Steel Plate, SECC, SGCC, Stainless Steel plate, Aluminum plate.DX51 DX53

- Stainless Steel: SUS304, SUS316, SUS316L, etc.

- Aluminum alloy:6063 5083 5052 6061,etc